Rowlands Modules – Setting the Standard

During 2013 Gareth Jones, one of our members, led an initiative to develop the standard published below for the building of ‘modules’ that can be brought together to form layouts either by an individual or by groups of people wanting to create something different every time they meet at an exhibition or event.

The original plan was to call them ‘Rowlands Modules’, as a nod to the CMEC 16mm group’s retired layout ‘Rowlands Lodge’, originally built by modular member and association member 0003, John Wenlock. This was however dropped to explain better in the name, what these modules were about, 16mm Association Modules.

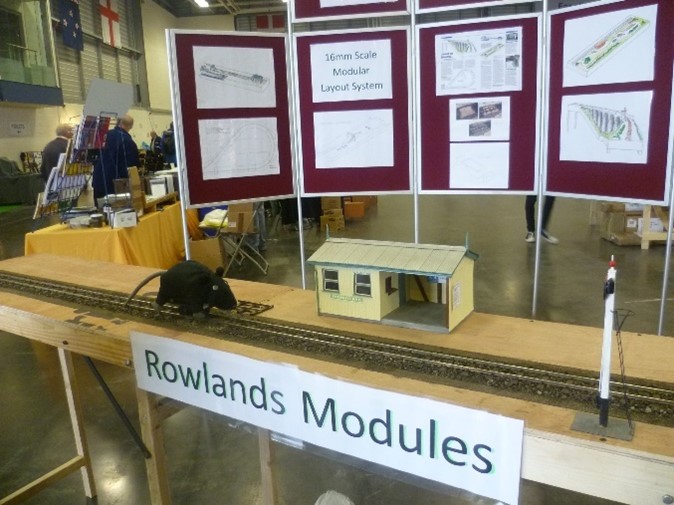

As Gareth said to those involved in setting this standard with him “First of all, many thanks to you all for joining me in this vision, I hope we can create something great between us”. These were the sample modules and stand with Gareth and Daniel Jones in attendance. Please note the late Brian Dominic’s Black Rat, which became the first, ahem ‘Vehicle’ to run on the modular system.

At the National Garden Railway Show

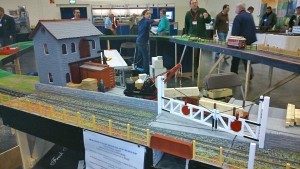

The modular layout has appeared at the National Garden Railway Shows at Peterborough Arena from 2014 onwards. Brian Dominic has kindly contributed these photographs from the 2015 show.

This huge collection of approx 80 modules (left and rear) at the 2018 Show, incorporating existing layouts ‘Glendreich’ and ‘Hen Feudy’. It looked very impressive when finished off with its curtains etc.

Here is a video of this impressive set up from a locomotive mounted camera by modular member, Alan McFarlane.

Further photographs

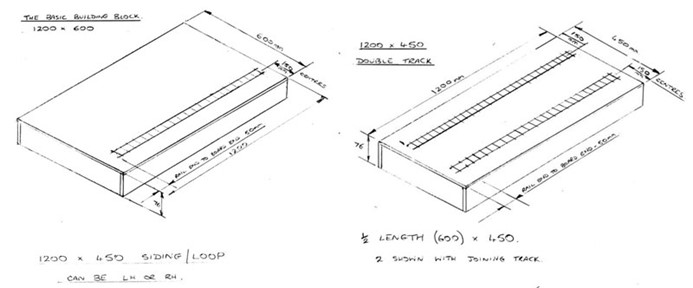

Baseboard Dimensions

The most important question is layout height. After discussion with layout owners and measuring the popular exhibition layouts of the day, a figure of 950mm to the baseboard to was arrived at. The track, which we ask to be PECO SM32 track at least at the ends, is a further 10mm in height. So, floor to rail top is 960mm.

Clearances are recommended such that it will accommodate the largest current ‘normal’ SM32 Rolling Stock. Typical large locomotives to handle are the VoR Swindon built 2-6-2T locos at 135mm wide, and the 180mm height of the K1 Garratt. Rarer is the Class 91 SAR Diesel @ 191mm tall and 135mm wide.

The longest British rolling stock that we can accommodate are the Leek & Manifold and Campbeltown & Machrihanish bogie coaches.

As for the board widths – the widths to be in multiples of 150 from 300mm upwards, 300, 450, 600, 750, etc.

Track centre from front edge of board, 150mm. Subsequent tracks at 150mm centres from this or multiples of 150 if a gap is being left for a platform, etc.

Baseboard Length 1200mm being the standard, double or half lengths being useful too. If we are building the layout at a show in ‘Circuit’ form, then this is important.

It we configure the layout as ‘end to end with return loops’, then lengths are not important. If adapting a current layout, building ‘Adaptor Boards’ to connect to standard modules, it makes sense if it makes the whole assembly a multiple of 1200mm.

Layout Curtains

These to be made of a fire-resistant material. Approximately 850mm top to bottom. Most of those made to date are navy blue, although black and brown also exist. Some are pleated, some are not. It all depends on the skill of the sewing machinist. Short (approx. 25mm to 30mm) lengths of Velcro, mesh side, are sewn to the tops of these curtains approx. 20mm from the top. The equivalent ‘hooked’ side tape to be self-adhesive and applied as a continuous strip approx. 10-20mm from the top of the layout side frames.

Track

As stated previously, PECO SM32 track to be used at the very least at board ends, this will enable common connecting. Large radius points to be used wherever possible on the main running line/lines.

Initially, we had mentioned in the Standard that at the very least, the main running line was to have rails insulated from each other to allow easy electrification. In practice, this has not been taken up by any of the members and the idea has been dropped.

Track to end 50mm from the end of the board. Joints to be made with ‘drop in’ 100mm lengths of PECO track. In practice we will have a range of short pieces in 1mm increments from approx 97m to approx 103mm.

Alternative Approach

An alternative approach developed by Jon Mead and Laurence Smith is to add the ballast and the sleepers, with their chairs removed. This eliminates the mess and time factor taken by loose ballasting.

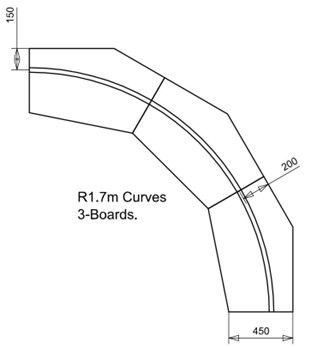

Clearance on straights and curves (R1697 min) to be 150mm wide (75mm each side of track centreline), 200mm tall.

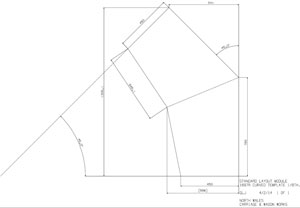

If making curved boards, the standard radius is 1.7m (actually R1697) this is approximately 5’ 7” . Smaller radii in reducing increments of 150mm have also been built, see below.

For those with an inquisitive mind, reverse curves of Radius 1697 give a parallel length of 2.4m, ie 2 x 1.2m, hence the selection of this unusual figure.

SM45

There has been some interest in SM45 or dual gauge versions of ‘Modular’. The Hampshire Group have developed this idea with their exhibition layout, pictured below. They have 32mm track, 150mm from one edge of the boards and 45mm from the opposite edge. Please contact them for further details – their group leader is listed in the ‘Bulletin’.

Baseboard Materials

The choice of material is solely up to the builder. Ply has proven to be very suitable for baseboard tops, approx. 9-12mm thick. Softwood has generally been used for the frames. Some have opted for more modern materials, eg foamboard with ply ends and sides. Thought must be given to fire resistance tho’. MDF is not normally a desirable material, as, untreated, it absorbs water and swells. It is also relatively heavy. Weatherproof plastic ‘Soffit board’ has been suggested but not been trialled yet. Using this and brass screws/glue would allow baseboards to be kept outside and possible planted with real plants!

Legs have generally been wooden, with adjustability of the feet being desirable. The ability to fold them away within the frames cuts down on stowage space.

Baseboard Joining

The standard method for modules to be joined is by 2-off 3” steel, screw type ‘G’ clamps. Minimum baseboard frame depth at the ends to be 76mm including top surface. Where deeper, cut-outs to be incorporated to accommodate the throat of the clamps.

On my initial units, I bolted end boards, joining to baseboards with tracks facing inwards. This forms a solid cube.

See photo. The 7mm diameter holes for this can be used as secondary methods of joining the boards together.

Legs to be of such a design that they do not affect the placing of the clamps. Cross bracing to be set down from the top of the boards.

Optional Bolted Method

To reduce the amount of clamps we need to use joining the baseboards together, an optional system of bolting with M6 Bolts, 6mm penny washers and wing nuts has been drawn up. This system does not suit all baseboards; however, it does work on some boards, and has been successfully used by many members to date. There should still be the availability of using ‘G’ clamps to maintain flexibility.

Passing Loops

Passing loops to be capable of accommodating an average 4-Bogie Coach plus average loco – min.

4 x 44’ + 30’ = 206, Divide by 19, = 11’.

Carpentry

Please ensure a reasonable standard of carpentry, in particular, baseboard mating faces to be square to the tops. Strength is vital! It’s a fairly common occurrence for an Exhibition Manager to come up to a nearly complete layout and ask for it to be bodily moved by ‘X’ amount! This places a tremendous strain on the construction.

As my woodwork teacher memorably told me during my first ever lesson – this is not a square, holding up what clearly was a carpenter’s square, with steel blade and wooden stock. He then flamboyantly checked it by scribing a perpendicular line from the edge of a plank of wood, then turning the square over and scribing a line on top of the previous, checking that they didn’t diverge. THIS is a square, he announced triumphantly!! That lesson has stayed with me! Likewise, he promoted checking tape measures against a quality steel rule – the end stop is prone to bending.

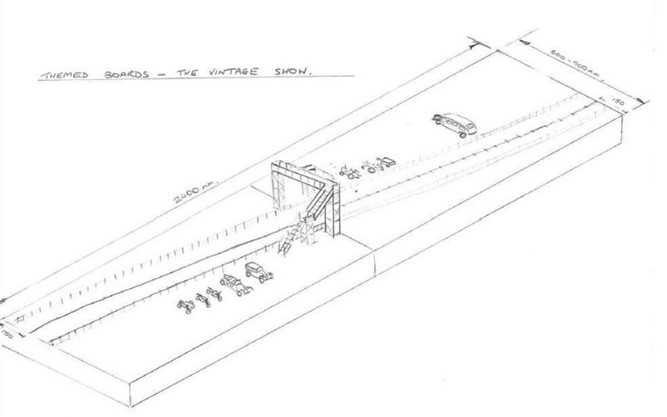

Typical Baseboards

These are very basic, and I hope you will all quickly stray away from the ‘Track parallel to the baseboard edge’ look. Please keep in mind that it is the ends that need to be modular, not the content in between, within the limits of clearance of course.

Steam-up area

The following two photographs show progress on a steam-up area, which made its first appearance at the 2015 National Garden Railway Show, providing a much-needed facility for the modular layout.

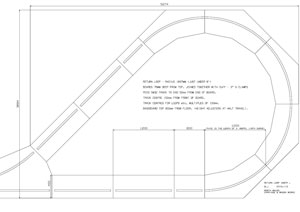

Corner Specification

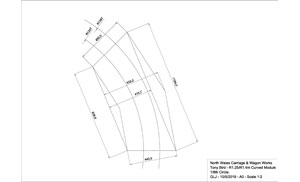

The following two drawings have been produced to enable a complete circuit to be built for operation at shows etc. Click on the link below either of the thumbnail pictures below to download a pdf copy of the relevant drawings.

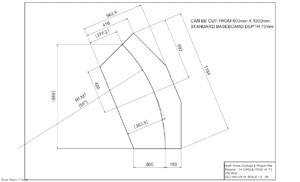

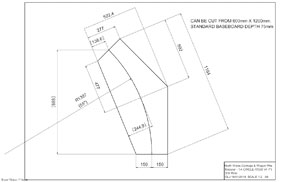

Smaller Radius Curve

In response to a call for slightly smaller radius curves, Gareth has drawn these two baseboards, 2 sizes, ie 300mm less radius than the current ‘Standard’ Curve. These are approx 4′ 7″ radius.

Gareth has drawn them as standard 450 width and 300 width; the latter will allow reverse curves to be made with a suitable joining transition straight between them (which he will draw next). A great advantage of these new drawings is that both can be cut from a standard 1200 x 600 sheet of plywood.

We have a shortage of curved boards – hopefully these will inspire perhaps the newer members to get cutting and sawing! As curved module owners, you will be very much in demand!

Tony Bird has also drawn a variant with double track, 1397mm and 1247mm radius.

Tony Bird has also published a video illustrating his method of constructing the 1297mm & 1247mm double track boards – this is one person’s interpretation of making modules, and by no means the ‘official line’.

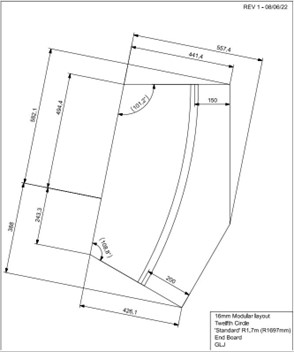

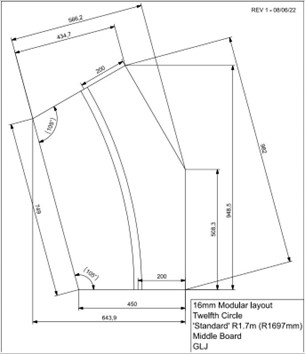

Standard Radius Curve – 12th Circle

These new boards take up less space and allow easier stacking than the previously drawn 1/8th circle examples. They can be cut in one piece from a standard 1200mm x 600mm Sheet of ply.

The Modular Cup

Gareth Jones introduced this cup to promote the building of modules to a high standard. Please see the MOTY (Model of the year) Competition on the National Garden Railway Show website.

Adapting Existing Layouts

When I originally conceived this idea, the thought that existing layouts could be adapted to form part of the Modular ‘System’ was part of the plan. In the intervening years, this has happened with the South Birmingham Group’s ‘Hen Feudy’ and the West of Scotland’s ‘Glendreich’ Whisky Distillery.